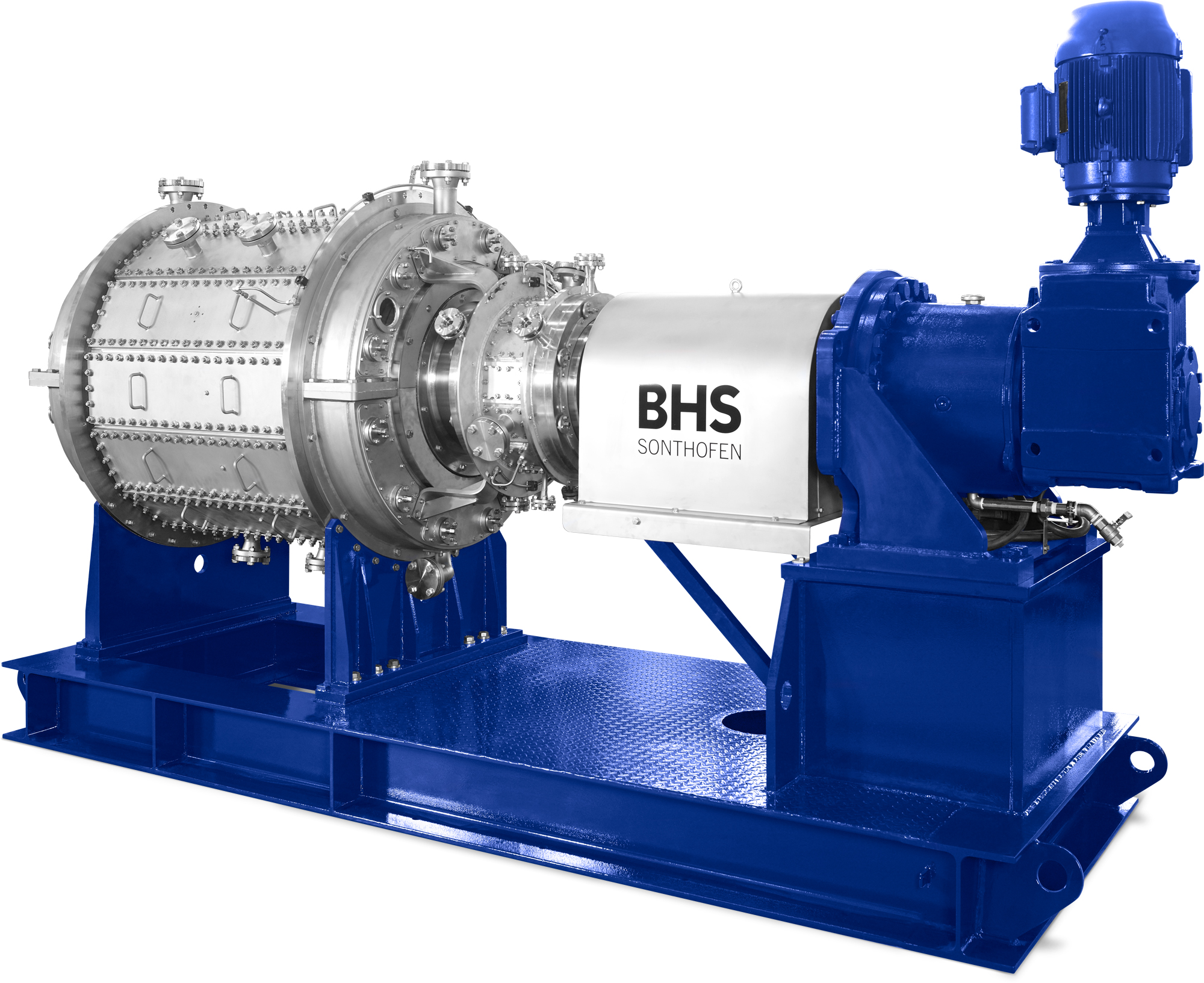

German specialists in solid-liquid filtration, BHS-Sonthofen, recently analysed a food additive manufacturer’s filtration process and suggested rotary pressure filters as an alternative to the company’s existing three peeler centrifuges.

The centrifuges were being used in a single production step and the manufacturer planned to replace them with three new, identical machines. Prior to that, the company asked BHS-Sonthofen to take a close look at the process step itself.

When the filtration process was analysed, BHS-Sonthofen found that the use of a rotary pressure filter would offer distinct advantages to the plant operator. The slowly rotating single unit required much less power, wash-liquid and maintenance and the quantity and quality of the yield increased significantly.

Laboratory tests were carried out that simulated the process on a small scale and the findings confirmed that the rotary pressure filter works more effectively than the centrifuges. The averaged cake washing results were improved by around 90%. The production of a solids-free filtrate meant there were no product losses as there had been with the centrifuges and a single filter was able to replace the three centrifuges.